Video

Preparation time: 10 min

Process time: 1 hour

Materials

- Coated paper (NB-Wf-3GF100)

- SMA (Bio Metal Helix)

- Wires (2 colors)

- Heat shrinkable sleeve

- MOSFET J681 2 pieces

- Solder

- Pins header

Tools

- Pen

- Arduino

- Solder

- Bread board

- Ruler

- Nipper

Directions

Prepare the laser cutter

Send the data to the laser cutter and adjust the settings. (Height, Volume, Power for each colored line, etc.)download : origami_cutting_pattern

Setting for Manual Control

– Black : Power 15.0%, Speed 100%, PPI 67, Z-Axis Off, Laser Both

– Red : Power 5.0%, Speed 92%, PPI 500, Z-Axis Off, Laser Both

– Green : Power 36.8%, Speed 61%, PPI 267, Z-Axis Off, Laser Both

– Yellow : Power 16.4%, Speed 100%, PPI 500, Z-Axis Off, Laser Both

– Blue : Power 8.5%, Speed 40%, PPI 500, Z-Axis Off, Laser Both

Send the data to the laser cutter and adjust the settings. (Height, Volume, Power for each colored line, etc.)download : origami_cutting_pattern

Setting for Manual Control

– Black : Power 15.0%, Speed 100%, PPI 67, Z-Axis Off, Laser Both

– Red : Power 5.0%, Speed 92%, PPI 500, Z-Axis Off, Laser Both

– Green : Power 36.8%, Speed 61%, PPI 267, Z-Axis Off, Laser Both

– Yellow : Power 16.4%, Speed 100%, PPI 500, Z-Axis Off, Laser Both

– Blue : Power 8.5%, Speed 40%, PPI 500, Z-Axis Off, Laser Both

Set the paper

Laser cut the paper

Fold the robot

Check the movement

Make the fold in the middle of the robot move softer by gently scraping it with a scissor blade.

Make the fold in the middle of the robot move softer by gently scraping it with a scissor blade.

Prepare the SMAs

Cut 2 SMAs in the length of 10mm. The SMA is usually wrapped around a cable. Gently separate the SMA form the cable by turning it gently to take out the cable. Throw the cable away, the remaining part is the SMA.

Cut 2 SMAs in the length of 10mm. The SMA is usually wrapped around a cable. Gently separate the SMA form the cable by turning it gently to take out the cable. Throw the cable away, the remaining part is the SMA.

Wire the SMAs and pins

Cut 4 wires in the length of 45cm. Make one knot at each end of the wire. Gently pull the SMA to stretch out the ends of the wire. Insert the edge of a SMA to the wire’s knot. Tie the knot with SMA in between.

Cut 4 wires in the length of 45cm. Make one knot at each end of the wire. Gently pull the SMA to stretch out the ends of the wire. Insert the edge of a SMA to the wire’s knot. Tie the knot with SMA in between.

SMA

Done! Make 2 pieces of SMA. There is another Recipe to explain how to make SMA.

Done! Make 2 pieces of SMA. There is another Recipe to explain how to make SMA.

Soldering

Make a knot at the other end of each wire. Tie the wire to the pin and solder them together.

Make a knot at the other end of each wire. Tie the wire to the pin and solder them together.

Sleeving

Cover it with the heat shrinkable sleeve.

Cover it with the heat shrinkable sleeve.

Marking center

Mark the center of the paper with a pen. Cut shallow slits with scissors.

Mark the center of the paper with a pen. Cut shallow slits with scissors.

Attach the SMAs

Pass the SMA through the slits.

Pass the SMA through the slits.

Circuit

Connect the SMAs to a circuit. Make your own designs and test various types of locomotion.

Connect the SMAs to a circuit. Make your own designs and test various types of locomotion.

Arduino Control

You can design the movement of Origami Robot by controlling SMA with Arduino.

You can design the movement of Origami Robot by controlling SMA with Arduino.

More Information

- Instructor in video : Lee Dongchi

- Paper : D. Lee, K. Saito, T. Umedachi, T. D. Ta, and Y. Kawahara, “Demo: Origami Robots with Flexible Printed Circuit Sheets,” Adjunct Proc. of ACM UbiComp 2018, pp. 392-395, Singapore, Oct. 2018.

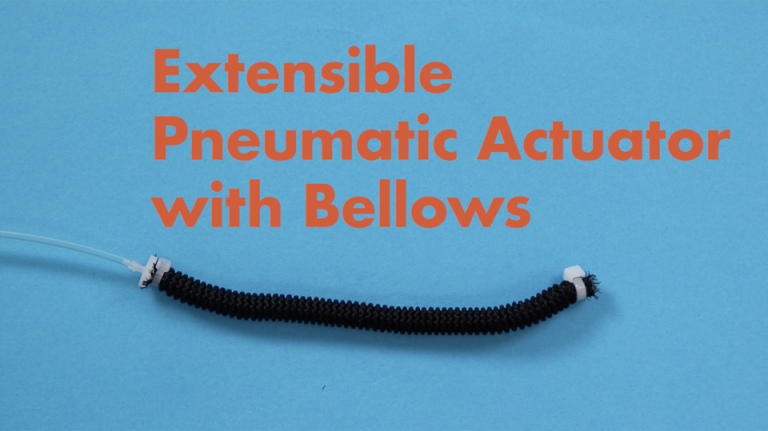

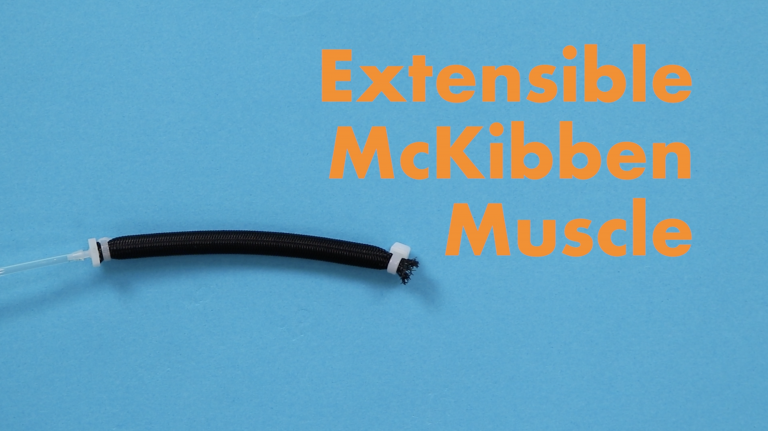

Cut the braided sleeve in the four times the length of the desired muscle length, for example 320mm (=80m x 4).

Cut the braided sleeve in the four times the length of the desired muscle length, for example 320mm (=80m x 4).

Insert a metal rod into the braided sleeve. Tie up the end of the rod and sleeve together with a cable tie. Push the sleeve along the rod and make bellows until no more shortening.

Insert a metal rod into the braided sleeve. Tie up the end of the rod and sleeve together with a cable tie. Push the sleeve along the rod and make bellows until no more shortening.

Then tie up the other end of the sleeve.

Then tie up the other end of the sleeve.

Bake in an oven at 120°C (248°F) for 20 minutes to fix the shorten state.

Bake in an oven at 120°C (248°F) for 20 minutes to fix the shorten state.

Put marks with tapes on the shortened sleeve with rod in the desired length, for example 80mm. Release the sleeve from the rod and cut the sleeve according to the marks.

Put marks with tapes on the shortened sleeve with rod in the desired length, for example 80mm. Release the sleeve from the rod and cut the sleeve according to the marks.

Cut the rubber tube in the same length.

Cut the rubber tube in the same length.

Insert the barbed plug into the end of rubber tube.

Insert the barbed plug into the end of rubber tube.

Insert the rubber tube into the braided sleeve.

Insert the rubber tube into the braided sleeve.

Tie up the end of the tube and sleeve together with a cable tie over the barbed plug. Tighten the cable tie to prevent air from leaking. Cut off the excess strap of the cable tie.

Tie up the end of the tube and sleeve together with a cable tie over the barbed plug. Tighten the cable tie to prevent air from leaking. Cut off the excess strap of the cable tie.

Insert the barbed connector into the other end of the rubber tube.

Insert the barbed connector into the other end of the rubber tube.

Tie up the end of tube and sleeve together with a cable tie over the barbed connector. Tighten the tie to prevent the tubes from slipping off. Cut off the excess strap of the cable tie.

Tie up the end of tube and sleeve together with a cable tie over the barbed connector. Tighten the tie to prevent the tubes from slipping off. Cut off the excess strap of the cable tie.

Connect the air tube and syringe to inflate the rubber tube and contract the artificial muscle.

Connect the air tube and syringe to inflate the rubber tube and contract the artificial muscle.

Test other recipes, too.

Bon Appétit! (but don’t eat)

Test other recipes, too.

Bon Appétit! (but don’t eat)

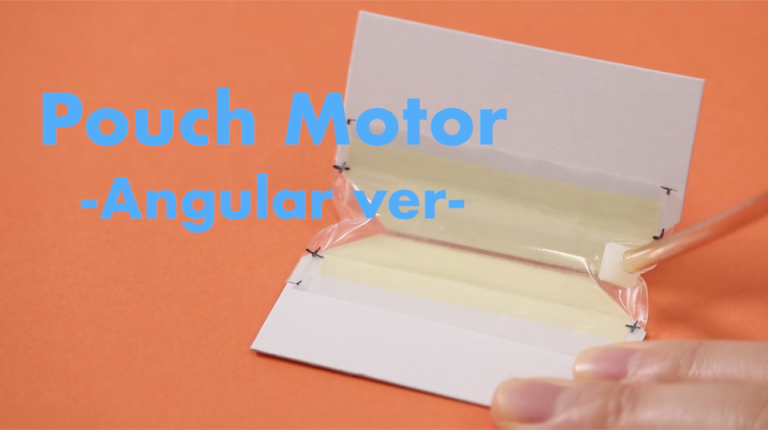

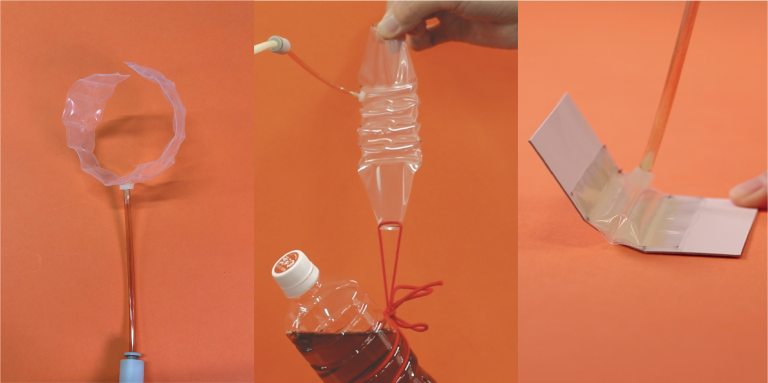

Put a film on a printed pattern and trace the shape with crosses or dots with a pen.

Put a film on a printed pattern and trace the shape with crosses or dots with a pen.

Cut a pair of films bigger than the pattern.

Cut a pair of films bigger than the pattern.

Adjust a timer dial of a heat sealer to the lowest setting that will still seal the films (maybe around 2.5).

Place a pair of films on the sealer. Adjust the position to make sure that the crosses/dots are on the sealing line. Push the sealing arm down and keep the arm down for 3-4 seconds.

Repeat the sealing process to make a square pouch.

Adjust a timer dial of a heat sealer to the lowest setting that will still seal the films (maybe around 2.5).

Place a pair of films on the sealer. Adjust the position to make sure that the crosses/dots are on the sealing line. Push the sealing arm down and keep the arm down for 3-4 seconds.

Repeat the sealing process to make a square pouch.

Cut the margin of the films along the outline of the pouch.

Cut the margin of the films along the outline of the pouch.

Make a cross/dot to mark the position of an air inlet hole with a pen. Fold the films crosswise around the mark. Cut a VERY small piece off from the corner of the films with a scissors.

Make a cross/dot to mark the position of an air inlet hole with a pen. Fold the films crosswise around the mark. Cut a VERY small piece off from the corner of the films with a scissors.

Unfold the films to check the hole. The diameter of the hole must be around 1-2mm. If it’s too big, cover the hole with a tape and try again on the other side.

Unfold the films to check the hole. The diameter of the hole must be around 1-2mm. If it’s too big, cover the hole with a tape and try again on the other side.

Apply a both-sided tape on the bottom of a connector. Make a through hole with an awl.

Apply a both-sided tape on the bottom of a connector. Make a through hole with an awl.

Fix the connector on the hole of the pouch.

Fix the connector on the hole of the pouch.

Cover the another hole on the flip side with a tape.

Cover the another hole on the flip side with a tape.

Make two square pieces of paper boards fit to the size of pouch to make a tabs. Apply both-sided tape on the one side of the piece. Cut two corners off a square.

Make two square pieces of paper boards fit to the size of pouch to make a tabs. Apply both-sided tape on the one side of the piece. Cut two corners off a square.

Fix two square pieces of paper board on the both side of the pouch.

Fix two square pieces of paper board on the both side of the pouch.

Connect a syringe and tube to the pouch. Push the air into the pouch to see the inflation of the pouch make a flapping motion. Try different sizes!

Connect a syringe and tube to the pouch. Push the air into the pouch to see the inflation of the pouch make a flapping motion. Try different sizes!

Put a film on a printed pattern and trace the shape with crosses or dots with a pen.

Put a film on a printed pattern and trace the shape with crosses or dots with a pen.

Cut a pair of films bigger than the pattern.

Cut a pair of films bigger than the pattern.

Adjust a timer dial of a heat sealer to the lowest setting that will still seal the films (maybe around 2.5).

Seal ONLY the outer lines of the pattern. Do NOT seal partition lines with a small gap. Place a pair of films on the sealer. Adjust the position to make sure that the crosses/dots are on the sealing line. Push the sealing arm down and keep the arm down for 3-4 seconds.

Repeat the sealing process to make a big square outline.

Adjust a timer dial of a heat sealer to the lowest setting that will still seal the films (maybe around 2.5).

Seal ONLY the outer lines of the pattern. Do NOT seal partition lines with a small gap. Place a pair of films on the sealer. Adjust the position to make sure that the crosses/dots are on the sealing line. Push the sealing arm down and keep the arm down for 3-4 seconds.

Repeat the sealing process to make a big square outline.

You can make a gap in the middle of sealing line with a paper board tape. Put a narrow paper board on the sealer, then make a partition lines on the inside of the pouch. The gap become tunnels between subdivided pouches.

You can make a gap in the middle of sealing line with a paper board tape. Put a narrow paper board on the sealer, then make a partition lines on the inside of the pouch. The gap become tunnels between subdivided pouches.

Cut the margin of the films along the outline of the pouch.

Cut the margin of the films along the outline of the pouch.

Connect a syringe and tube to the pouch. Push the air into the pouch to see the inflation of the pouch make a flapping motion. Try different sizes/shapes!

Connect a syringe and tube to the pouch. Push the air into the pouch to see the inflation of the pouch make a flapping motion. Try different sizes/shapes!

モミモミしてくれる〜。

モミモミしてくれる〜。

もじゃもじゃウニョウニョ

もじゃもじゃウニョウニョ

ほっぺたプニプニ

ほっぺたプニプニ

キラキラ〜。

キラキラ〜。

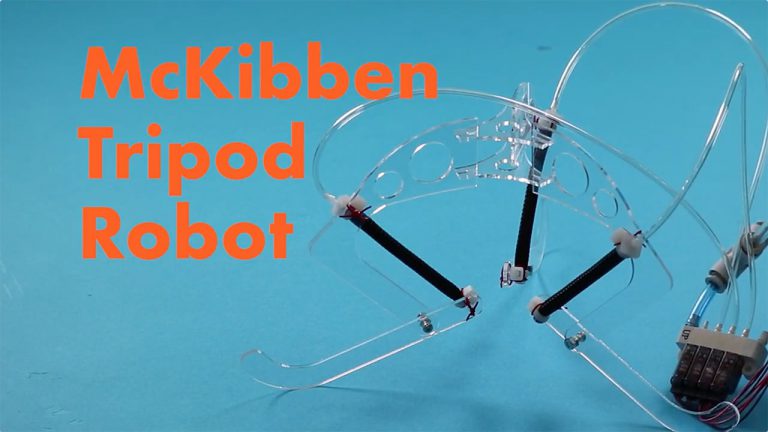

Make a connection between two leg links with a screw and two nuts. Make sure you have little clearance between first nut and the acrylic plate. Tightening second nut on the first nut makes locking effect. It’s become a knee joint.

Make a connection between two leg links with a screw and two nuts. Make sure you have little clearance between first nut and the acrylic plate. Tightening second nut on the first nut makes locking effect. It’s become a knee joint.

Put wire on the head of nylon tie of both ends of the muscle.

Put wire on the head of nylon tie of both ends of the muscle.

Tie the muscle to the leg. One end to the knee and another end to the heel.

Tie the muscle to the leg. One end to the knee and another end to the heel.

Put all three legs together on the body plates.

Put all three legs together on the body plates.

Insert tubes into all three muscle. Supply pressured air to the muscles with syringes or air compressor. Pneumatic solenoid valves can be used to on/off control of the muscles.

Bon Appétit! (but don’t eat)

Insert tubes into all three muscle. Supply pressured air to the muscles with syringes or air compressor. Pneumatic solenoid valves can be used to on/off control of the muscles.

Bon Appétit! (but don’t eat)

Cut the rubber tube in the desired length, for example 80mm. Cut the braided sleeve in the same length as the rubber tube.

Cut the rubber tube in the desired length, for example 80mm. Cut the braided sleeve in the same length as the rubber tube.

Insert the barbed plug into the end of rubber tube.

Insert the barbed plug into the end of rubber tube.

Insert the rubber tube into the braided sleeve. Tie up the end of the tube and sleeve together with a cable tie over the barbed plug. Tighten the cable tie to prevent air from leaking. Cut off the excess strap of the cable tie.

Insert the rubber tube into the braided sleeve. Tie up the end of the tube and sleeve together with a cable tie over the barbed plug. Tighten the cable tie to prevent air from leaking. Cut off the excess strap of the cable tie.

Insert the barbed connector into the other end of the rubber tube.

Insert the barbed connector into the other end of the rubber tube.

Tie up the end of tube and sleeve together with a cable tie over the barbed connector. Tighten the tie to prevent the tubes from slipping off. Cut off the excess strap of the cable tie.

Tie up the end of tube and sleeve together with a cable tie over the barbed connector. Tighten the tie to prevent the tubes from slipping off. Cut off the excess strap of the cable tie.

Connect the air tube and syringe to inflate the rubber tube and contract the artificial muscle.

Bon Appétit! (but don’t eat)

Connect the air tube and syringe to inflate the rubber tube and contract the artificial muscle.

Bon Appétit! (but don’t eat)

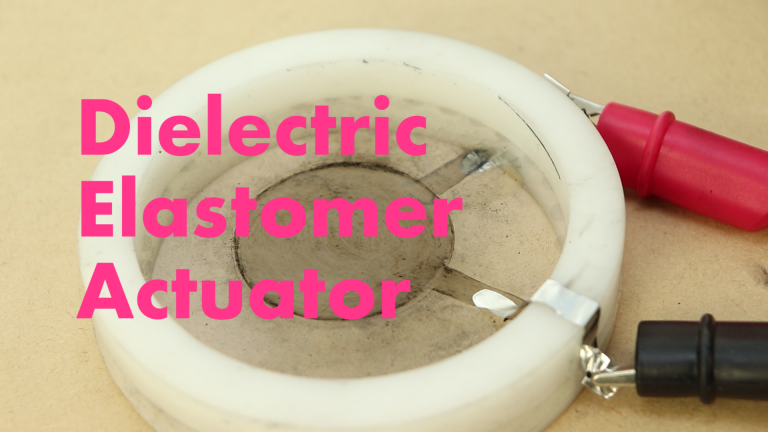

Cut the elastomer sheet in the size of 80mm x 80mm. Place the sheet on the guide paper with the sticky side facing up. Draw the guide line on the elastomer sheet. The diameter of the circle is 26.6mm.

Cut the elastomer sheet in the size of 80mm x 80mm. Place the sheet on the guide paper with the sticky side facing up. Draw the guide line on the elastomer sheet. The diameter of the circle is 26.6mm.

Peel off the film from the elastomer sheet. Put the sheet on the acrylic frame and stretch it little by little. This process adds triaxial strain, which has the effect of thinning the film’s thickness, constraining the direction of movement, improving the withstand voltage, and controlling rigidity.

Peel off the film from the elastomer sheet. Put the sheet on the acrylic frame and stretch it little by little. This process adds triaxial strain, which has the effect of thinning the film’s thickness, constraining the direction of movement, improving the withstand voltage, and controlling rigidity.

Stretch the elastomer sheet until the guide line meets the acrylic frame.

Stretch the elastomer sheet until the guide line meets the acrylic frame.

Cut the excess elastomer sheet off. The frame is done!

Cut the excess elastomer sheet off. The frame is done!

Place the stencil sheet on the center of the frame. The diameter of the circle is 30mm and the width of the wiring part is 5mm.

Design of the Stencil Sheet

Place the stencil sheet on the center of the frame. The diameter of the circle is 30mm and the width of the wiring part is 5mm.

Design of the Stencil Sheet

Put a single dose of carbon powder on the elastomer sheet with a spatula. Spread it on the sheet as thin and as even as possible with a brush.

Put a single dose of carbon powder on the elastomer sheet with a spatula. Spread it on the sheet as thin and as even as possible with a brush.

Discard the excess powder and remove the stencil sheet.

Discard the excess powder and remove the stencil sheet.

Place the other acrylic frame on top. Turn it over to make another electrode on the opposite side. Do the same process from “Stencil sheet”. But the electrode should be rotated 90 degrees.

Place the other acrylic frame on top. Turn it over to make another electrode on the opposite side. Do the same process from “Stencil sheet”. But the electrode should be rotated 90 degrees.

Cut the aluminum tape in the width of the electrode’s wiring part. Attach the tape to the wiring parts on each side of the elastomer sheet. Fold the excess tape.

Cut the aluminum tape in the width of the electrode’s wiring part. Attach the tape to the wiring parts on each side of the elastomer sheet. Fold the excess tape.

Connect the electrodes to a high voltage power supply. For safety, ensure that the negative electrode is on the top. (The positive electrode is dangerous!). The voltage should be around 0~5.5kV.

Connect the electrodes to a high voltage power supply. For safety, ensure that the negative electrode is on the top. (The positive electrode is dangerous!). The voltage should be around 0~5.5kV.

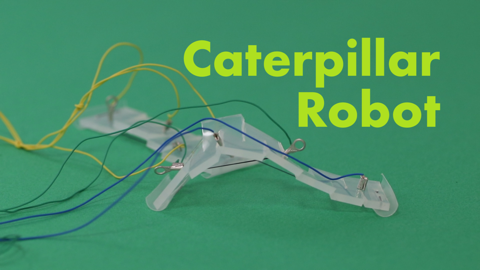

Cut the rubber sheet in the size of 7cm x 2cm. Also cut 2cm of the straw and cut it vertically in half.

Cut the rubber sheet in the size of 7cm x 2cm. Also cut 2cm of the straw and cut it vertically in half.

Cover the edge of the rubber sheet with the straw and staple it. This makes the edges slippery, which makes the caterpillar’s locomotion smoother. Cover the other edge of the rubber sheet with the straw and staple it in the same direction.

Cover the edge of the rubber sheet with the straw and staple it. This makes the edges slippery, which makes the caterpillar’s locomotion smoother. Cover the other edge of the rubber sheet with the straw and staple it in the same direction.

Cut slits in 1/2~2/3 the width of the rubber sheet. Do this for both sides, making sure the slits don’t overlap. The rubber sheet’s stiffness can be tuned by changing the cutting depth and the slit’s pitch.

Cut slits in 1/2~2/3 the width of the rubber sheet. Do this for both sides, making sure the slits don’t overlap. The rubber sheet’s stiffness can be tuned by changing the cutting depth and the slit’s pitch.

Pass the SMA through the slits of the rubber sheet. The distance between the two slits should be 2 times longer than the length of the SMA. Repeat this for the opposite side.

Refer to the illustration below.

Pass the SMA through the slits of the rubber sheet. The distance between the two slits should be 2 times longer than the length of the SMA. Repeat this for the opposite side.

Refer to the illustration below.

Briefly connect the power source to the SMA (0.5~1sec) by pressing each of the wires from one SMA to the positive red wire and the negative black wire of the battery case. The SMA will shrink when electric current is applied. Be careful not to connect it for too long or the SMA will burn out.

Briefly connect the power source to the SMA (0.5~1sec) by pressing each of the wires from one SMA to the positive red wire and the negative black wire of the battery case. The SMA will shrink when electric current is applied. Be careful not to connect it for too long or the SMA will burn out.

Connect the SMA, button switches and power on the breadboard. You can control the caterpillar robot with two button switches.

Image of the circuit diagram

Connect the SMA, button switches and power on the breadboard. You can control the caterpillar robot with two button switches.

Image of the circuit diagram

Make the robots together with your friends, and enjoy the race!

Make the robots together with your friends, and enjoy the race!