SMA changes its length when electric current is applied. This video explains how to make a SMA muscle.

Video

Materials

- SMA (Bio Metal Helix)

- Wire

- Heat shrinkable sleeve

- Pins

Tools and Equipments

- Crimp terminal

- Tape measure

- Nipper

- Pliers

- Tweezers

- Soldering iron

Directions

Cutting

Cut the two pieces of wire in the length of 50cm. Also cut the SMA in the length of 2cm.

Separate the SMA

The SMA is usually wrapped around a cable. Gently separate the SMA form the cable.

Tie

Tie the wire to the SMA.

Tighten

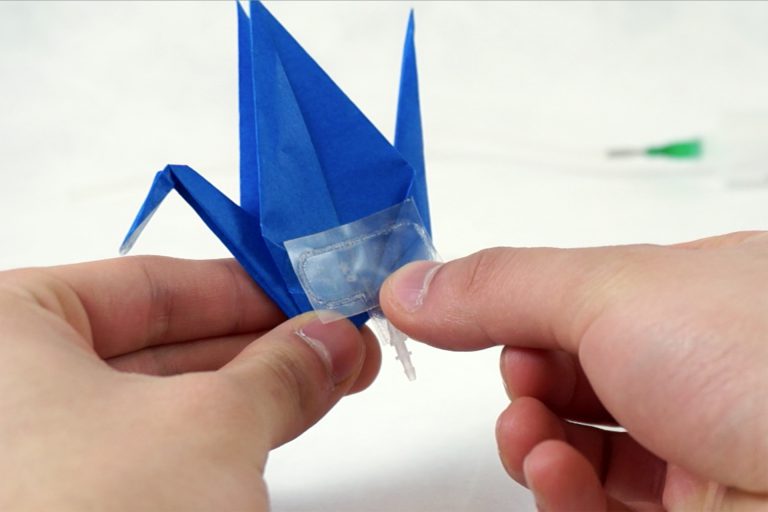

Pass the crimp terminal over the tied wire and press it strongly with pliers

Tie the other side

Repeat the same process.

Both sides are done

The SMA cable is connected to the wires.

Connect the pins

In order to make it easier to handle, we will connect pins. Tie the wire to a pin.

Soldering

Solder them together.

Coat

Cover it with a heat shrinkable sleeve.

Done

Connect another pin to the other end of the SMA’s wire.

Check

Briefly connect power. The SMA will shrink when electricity is applied.

Other recipes

- Application : Caterpillar Robot

- more recipes using SMA : Origami Robot (coming soon!)

More Informations

- Instructor in video : Takuya Umedachi

- Research work : Caterpilike (Kawahara Lab, The University of Tokyo)

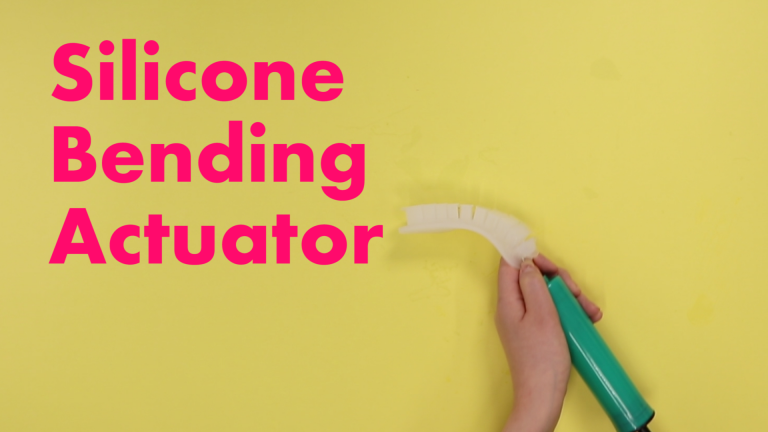

First, let’s see how much silicone rubber is needed for the mold. Pour water into the molds instead of silicone rubber. Gather the water into a cup and weigh it. This value is about the same amount of silicone rubber necessary to fill the molds. When measuring the silicon rubber, we will add an extra 10-20% to this amount.

First, let’s see how much silicone rubber is needed for the mold. Pour water into the molds instead of silicone rubber. Gather the water into a cup and weigh it. This value is about the same amount of silicone rubber necessary to fill the molds. When measuring the silicon rubber, we will add an extra 10-20% to this amount. Pour Ecoflex part A into a cup. It should be half of the required amount of silicon rubber. Pour the exact same amount of Ecoflex part B into the same cup. If you have poured more than the required amount of part B, then add more part A so that they are the equal amount.

Pour Ecoflex part A into a cup. It should be half of the required amount of silicon rubber. Pour the exact same amount of Ecoflex part B into the same cup. If you have poured more than the required amount of part B, then add more part A so that they are the equal amount. Slowly mix the silicone with a mixing stick for 1 minute. Avoid brisk mixing movements to prevent from making bubbles. Mix well while scraping the silicone from bottom and side of the cup.

Slowly mix the silicone with a mixing stick for 1 minute. Avoid brisk mixing movements to prevent from making bubbles. Mix well while scraping the silicone from bottom and side of the cup. The molds should be made of non-silicone material such as PP (polypropylene), PE (polyethylene), and PET (polyethylene terephthalate), otherwise the silicone mold will fuse with the casted silicone. Pour the silicone into the molds. Wipe off the overflowed silicon with a paper towel.

The molds should be made of non-silicone material such as PP (polypropylene), PE (polyethylene), and PET (polyethylene terephthalate), otherwise the silicone mold will fuse with the casted silicone. Pour the silicone into the molds. Wipe off the overflowed silicon with a paper towel. Leave the silicon rubber for 10 minutes for degassing. For simple molds, vacuum pumps are not necessary because Ecoflex’s viscosity is not that high.

Leave the silicon rubber for 10 minutes for degassing. For simple molds, vacuum pumps are not necessary because Ecoflex’s viscosity is not that high. Bake in an oven at 60°C (140°F) for 20 minutes to accelerate curing. If you don’t have a oven, just wait for 4 hours at room temperature.

Bake in an oven at 60°C (140°F) for 20 minutes to accelerate curing. If you don’t have a oven, just wait for 4 hours at room temperature. Take out the silicone rubber from molds. Cut off the excess silicon on the edges with scissors.

Take out the silicone rubber from molds. Cut off the excess silicon on the edges with scissors.